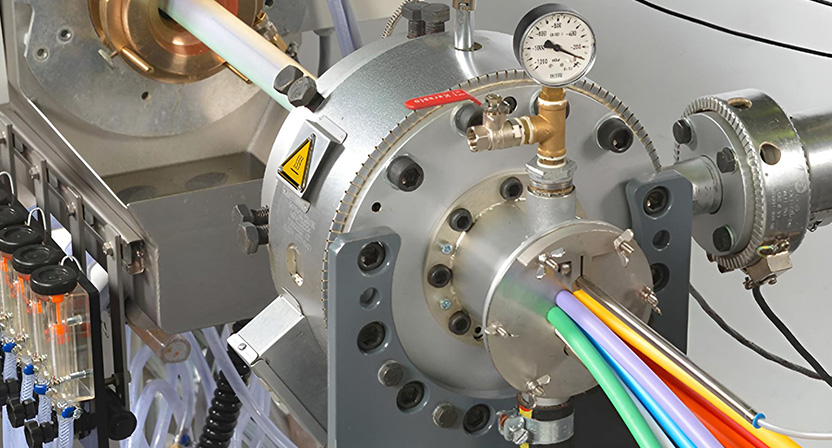

Innovative and economical: extrusion technology with a future

As technology leader in the extrusion industry, the battenfeld-cincinnati Group offers you comprehensive solutions for a wide range of applications. Our motto “Sustainable Solutions Worldwide” stands for our promise to ensure maximum performance, cost efficiency and sustainability in every project for you.

Please get in touch with us. We will be glad to advise you.

Our values:

We combine cost efficiency with sustainability in application-optimized solutions.

Circular Economy

Our innovative solutions allow the use of recycled material, produce in an energy-efficient manner and make your investment sustainable. High-Speed extruder melts and degasses granulate from used plastic.

Many different tasks, a pleasant working atmosphere and a future-proof situation: this is what our associates appreciate about battenfeld-cincinnati. Please find out more reasons why you should apply for a job with us.

Current information about battenfeld-cincinnati

Meet our team of extrusion experts at Chinaplas.

Find out how our groundbreaking innovations can help you optimize the energy efficiency of your extrusion process.

Don't miss this opportunity and come by!

Convince yourself of our exceptional expertise in plastic pipe extrusion by visiting us.

We offer you a customized solution tailored to your specific application. From the extruder to the complete line, we are the right partner for you.

Experience it personally!