FDC fast dimension change in pipe extrusion

Powerful and flexible operation

Complete lines for quick, in-line dimension change from a single source

Pipe manufacturers aiming to be competitive in production these days need extrusion lines which are powerful, flexible and quickly adjustable, as well as cost-efficient in operation. To meet these requirements, we have developed a system for automatic pipe dimension change during production. The system can be delivered as a complete solution, or the customer can choose individual components to retrofit his line.

Your Advantages:

- Efficient extrusion line with high throughput

- Material savings thanks to reduced change-over times

- High flexibility as to pipe geometry and production planning

Our Offer:

- High-performance extruders along with an inner pipe cooling system ensure highest productivity with low energy consumption

- Adjustable components over a particularly large diameter range

- Modular concept, from changing one adjustable component to a complete, automatically adjustable extrusion line, e.g. diameters 200 - 630 mm, comparable to standard extrusion lines

- Simple handling thanks to an extended control concept for automatic dimension change

- Excellent pipe quality with homogeneous pipe surface and even wall thickness distribution

- The FDC system is suited for the production of PE-HD single layer, as well as co-extruded multi-layer pipes

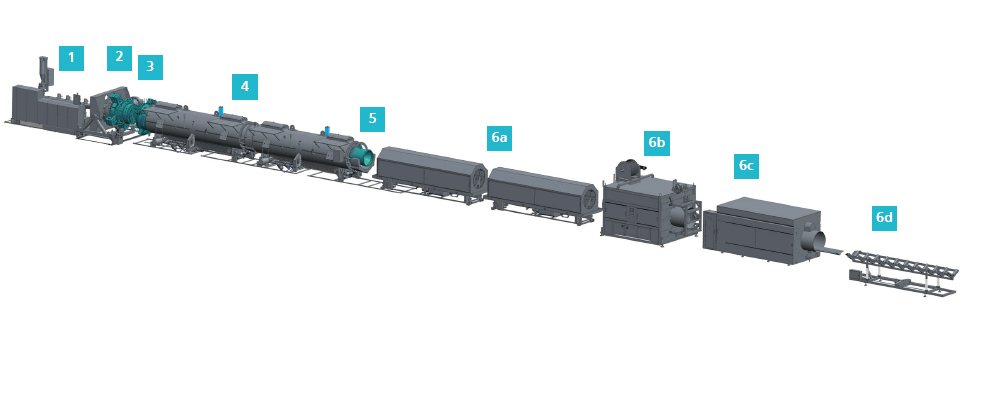

FDC line components

1: Extruder

2: Pipe head with adjustable melt gap (click here for more details about helix II pipe head with adjustable melt gap)

3: FDC adjustable calibration sleeve

4: Vacuum tank vacStream with adjustable pipe support

5: FDC adjustable vacuum sealing

6a: coolStream cooling tank

6b: pullStream haul-off

6c: cutStream cutting unit

6d: Tilting table

Please do not hesitate to contact us for more precise information regarding our new FDC components.