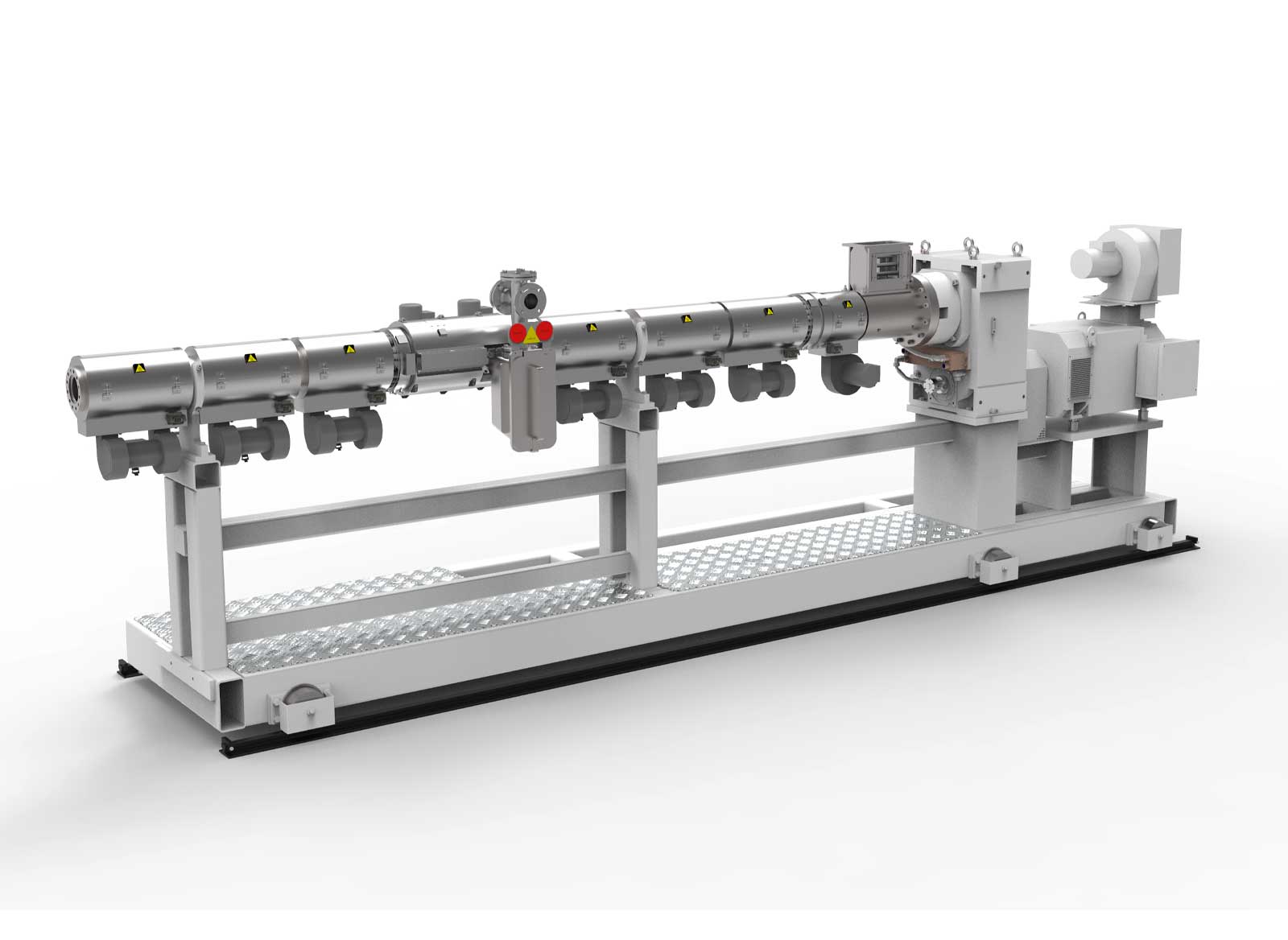

STARextruder

Efficient PET processing

The best for for processing of PET bottle flakes

Over the last few years, PET has been used more and more often for high-grade packaging, thanks to its high transparency, good mechanical properties and ample availability. However, the hygroscopic characteristics of PET during extrusion may lead to lower product quality. Thanks to their effective high-vacuum degassing with the proven planetary roller system, STARextruders offer the best conditions for high product quality.

Your Advantages:

- Energy savings through significant reduction of drying costs

- Robust, proven machine technology

- Increase in flexibility by saving drying times

- Easy operation of the process and maintenance-friendly system

- Changeover to PP or PS possible without screw change, if required

- Proven concept for processing of PET bottle flakes into food-grade thermoforming sheet (letter of non-objection received from FDA)

Our Offer:

- Machine sizes of 90, 120 and 150 mm

- Outputs from 600 - 1,200 kg/h

- High flexibility in PET processing

- Extremely low operation and maintenance costs

- Efficient extrusion for lower and medium output ranges

BCtouch UX control

- Supports OPC-UA Protocol

- Supports industry 4.0 functions

- Control mounted directly on the extruder cabinet or on a mobile stand

- Individually customizable user interface: adapted to every machine operator (language, icons, screen configuration)

- Up to 7 extruders can be integrated into the control