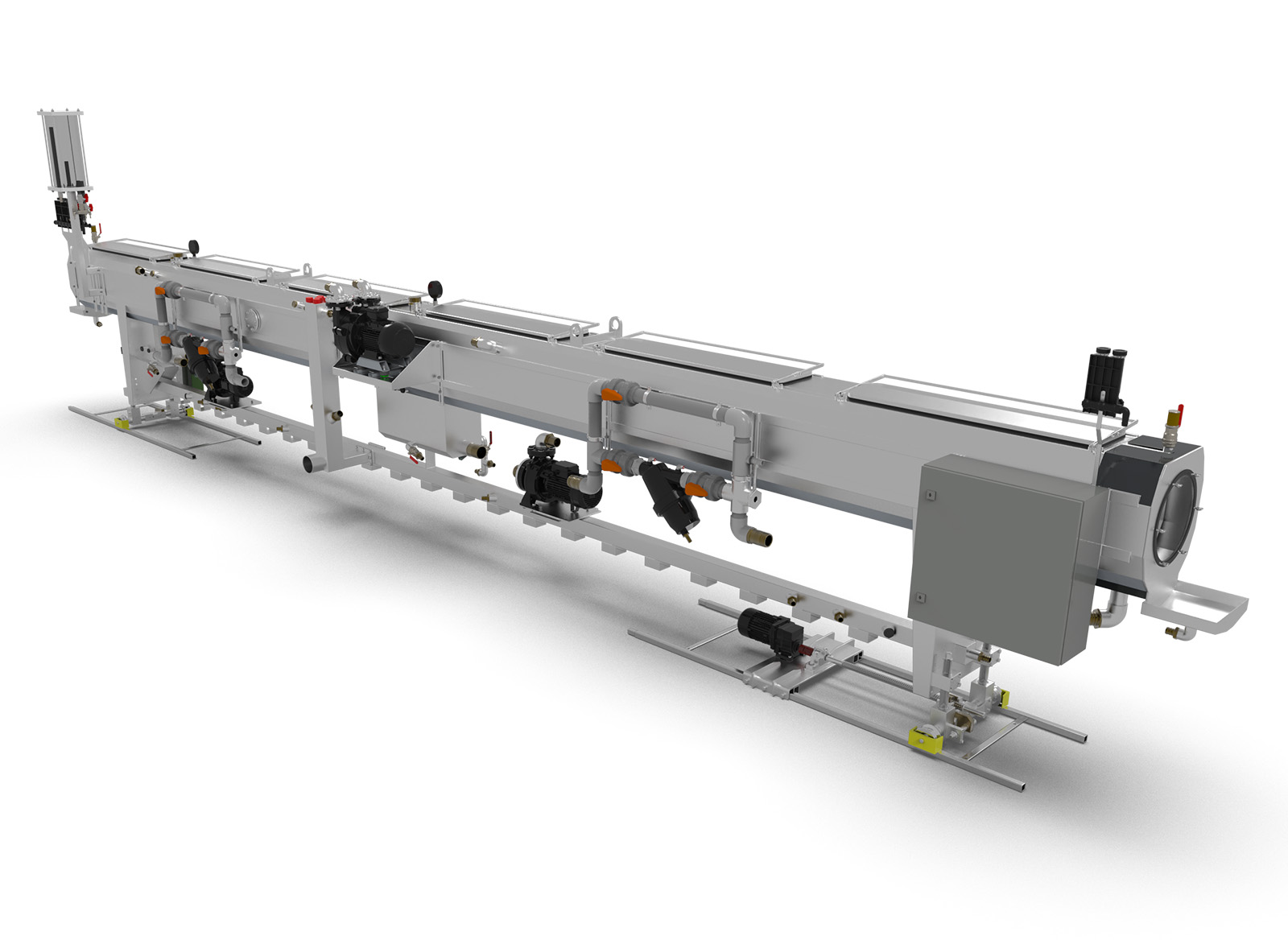

vacStream

Vacuum tanks for the PO and PVC pipe extrusion

The perfect solution for any size and application

Our vacuum tanks are adapted to the individual applications. We have the perfect solution for almost every size and requirement, as well as special applications such as our FDC (fast dimension change) system for automatic dimension change, or twin-strand extrusion.

In high-performance pipe extrusion, processors are faced with a variety of challenges like required line speed and surface quality. With the aid of high line competence, we are able to develop and implement outstanding solutions to offer highest degree of efficiency.

Your Advantages:

- Complete solutions made from stainless steel

- Flow-optimized piping made of corrosion-resistant materials

- Easy height, horizontal and longitudinal adjustment

- Cold water temperature control

- Energy savings with the help of optimally designed pumps

- Tanks customized to the application requirements

- Patented pipe support system for the FDC version

- Vacuum pumps can be frequency controlled optional

Our Offer:

- Vakuum tanks for pipe diameters up to 63 mm

- Vakuum tanks for pipe diameters up to 630 mm

- Vakuum tanks for pipe diameters from 800 mm and above

- Large diameter pipe extrusion of currently 1.600 mm (PVC) and 2.600 mm (HDPE)

Pipe diameter up to 63 mm

- Special versions for exact vacuum control and water quantity control

- Fine vacuum control optional

- Dual or multiple chamber versions

- Switchable between full and spray bath

- Integrated blow-off and drying units

- Integrated dry-running protection for the vacuum and water pumps

Pipe diameters up to 630 mm

- Tanks available in 6 m (single chamber), 9 m (dual chamber) with 1.5 m segments due to modular system

- Highly flexible configuration and long cooling section, due to barrier-free tank connection

- Extremely stable vacuum due to optimized process contro

- Highly advanced rail system aids the placement of components either under the tank or laterally

- All FDC components can be retrofitted at any time to single-chamber tanks

- Fast and easy sealing for vacuum generation through new lid design and longer service life of the sealings

- Symmetrical tank, which allows change of the operator side without structural alterations

Large diameter pipes from 800 mm and above

- Redundant water and vacuum pumps for safe operation and easier start-up

- Spray nozzle rods individually adjustable from the outside

- Double filter unit with automatic backwashing

- Changeover aids such as pulley and platforms inside the tank

- Easy access from above with the help of operator safety platform