For manufacturing virtually all kinds of extruded semi-finished products, battenfeld-cincinnati offers the right machinery and equipment, from customized single components all the way to optimized turnkey lines. The extrusion specialist based in Bad Oeynhausen, Germany thus serves customers from the pipe, profile and board industries as well as producers of film, sheet and granulates. “The special feature of our complete line is that they not only consist of perfectly synchronized individual components without any interface problems, but also come entirely from a single source”, is how the group’s Managing Director and CEO Gerold Schley describes its product range’s unique selling point. At the K, battenfeld-cincinnati will visualize its complete line competence for the first time by unveiling the new, consistent design of its pipe extrusion lines, this year’s winner of the coveted IF Award.

It is only logical, that the top issues of circular economy, digitization and climate protection at this year’s leading world trade fair precisely reflects what is on the mind of the entire plastics industry. “Our motto ‘Sustainable solutions worldwide’ has lost none of its actuality, so we are presenting extrusion equipment in Düsseldorf this year which meets our customers’ demands for concepts offering energy efficiency, space-saving footprints, low maintenance, flexibility and high performance”, Gerold Schley emphasizes.

Water management and new design for the pipe industry

At the K, battenfeld-cincinnati will unveil the new complete line standardised design, with which all pipe extrusion lines will be presented from 2023 onwards in the battenfeld-cincinnati corporate colours. Apart from the visual effect, the functionality of the new design is the most important attractive feature: optimal accessibility and user-friendliness including easy cleaning features are the main attributes. All aggregates starting from the extruder to the calibration and cooling units and the vacuum tank, right up to the cutting saw and the tilt table, are manufactured in-house by battenfeld-cincinnati, perfectly matched not only technically and now also visually, without any interface problems, and integrated into the intuitive-to-operate BCtouch UX control system.

battenfeld-cincinnati offers complete lines for the pipe industry to cover an enormous diversity of applications, ranging from drip irrigation in agriculture right up to large-diameter pipes for water management. Both these extremes will be shown at the K booth. In large-diameter pipes, a new record has actually been set. The first lines to produce pipes up to 2,700 mm in diameter have been delivered. Two highlights of the large-diameter pipe extrusion lines are the pipe die with Optimelt, providing ideal melt homogenization with lowest melt temperatures to minimize sagging. With the completely new constructed 4 m long segments of the downstream unit battenfeld-cincinnati addresses the enormous dimensions of the equipment and the related transport problems. For the first time, there are vacuum tanks and spray baths which come in segments only 4 m long. These single aggregates can easily be transported and are easy to assemble on the production site.

Visitors to the K booth can witness battenfeld-cincinnati’s drip irrigation expertise by a video presentation of the new line set up for customer test runs in its technical lab in Bad Oeynhausen. The highlight here are the drippers, which come in a design both simple and ingenious to ensure a very even continuous water dispensation. During the extrusion process these drippers, developed by battenfeld-cincinnati with a partner company, are shot through the pipe die and fully welded into the pipe at once while it is still hot. Drilling or punching holes in the drippers for the water outlets are no longer required. At the same time, the design of the drippers ensures a long service life on site without clogging of the water outlets with limescale, soiling or plant growth.

Another novelty at the K booth is the small solEX NG, which completes the high-speed extruder series for pipe extrusion at its smallest size. From now on, the solEX NG 45 will be available in addition to the four solEX NG models already existing in the sizes of 60, 75, 90 and 120 mm. A striking attribute of this series is the combination of internally grooved barrels with a matching special screw geometry, which offers several advantages: up to 40% higher outputs, about 10 °C lower melt temperatures and 15 % less energy consumption.

Ideal extrusion solutions for eco-friendly products

Floor coverings based on highly filled plastics have experienced enormous growth in recent years. These are often PVC-based formulations. In view of the sustainability discussions, it is becoming apparent that PP will take on a leading role in this area and partially replace PVC.

The requirements for floor coverings in terms of absence of tension, flatness and thickness tolerance are extremely high due to the following processing steps, such as printing, as well as the later application area. The semi-crystalline structure of PP makes the task even more difficult.

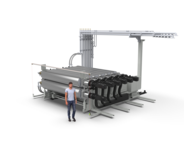

It turns out, that for the production of environmentally friendly floor coverings made of PP the Multi-Touch roll stack from battenfeld-cincinnati is very suitable. This was clearly demonstrated in practical use by several first customers. This unique roll stack, equipped with up to nine cooling rolls for pre-calibration and re-calibration, ensures a long phase of intense contact between the board and the cooling rolls after the melt has left the flat die. The cooling of the top and bottom side takes place almost simultaneously. In this way, a dimensionally accurate, visually attractive semi-finished product with ideal flatness and lowest thickness tolerances is created, which is perfect for flooring applications. Yet not only for floor coverings, but also for manufacturing refrigerator panels or other surface panels made of PS or PP, the roll stack is in demand internationally and already being used in many countries. At the K booth, a Multi-Touch roll stack will be exhibited, so that interested customers can exchange views with the relevant specialists about its wide range of applications, which even include the production of thin film smoothed on both sides.

battenfeld-cincinnati also offers perfect extruders for the PVC industry. The most recent proof is the new pelletizing extruder series aglomEX, available either with or without electrically driven shear gap adjustment (EMS). These extruders are suitable not only for virgin material, but also for PCR goods originating, for example, from the Rewindo collection system. The immediate eye-catcher on the model aglomEX 114 to be showcased at the booth is the processing unit lengthened by 6 D, with which all five models have been fitted. In this way, the extruders not only meet the demand of the PVC industry for capacity to process a range of raw materials as wide as possible, but they also achieve up to 20% higher output rates in response to the general call for high efficiency.

On course towards fully automatic extrusion lines

Automation and digitization not only facilitate daily production processes, but also fulfill the requirements for high efficiency in production, reduced set-up times and low scrap rates. Impressive examples are the systems developed by battenfeld-cincinnati for pipe and sheet production and presented at this year’s K. Fast dimension change (FDC) is a system which enables changes of pipe dimensions within a wide range of diameters at the push of a button during production. Not only the melt gap on the pipe die, but also all downstream aggregates adjust themselves simultaneously to the new pipe dimensions without any manual intervention. So, pipe manufacturers are able to fill even small-volume orders efficiently and to minimize the amount of scrap as well, which makes their production eco-friendlier. Similar helpers in daily production are on offer for sheet and board extrusion lines. For instance, combined operation of the extruder and the melt pump in sheet extrusion significantly facilitates start-up. This saves time and costs and minimizes start-up scrap. Automatic adjustment of the flat-sheet die and the roll stack, as well as the roll compensation system, also simplifies the operation and increase the efficiency in production.

At the K, battenfeld-cincinnati will also present Steady flow from its extensive range of individual modules, which is the solution to reduce pressure fluctuations in PVC extrusion. In the counter-rotating conical twin screw extruders frequently used in PVC extrusion, pressure fluctuations inside the die are unavoidable, due to the chamber profile. Yet these fluctuations may degrade the quality of the semi-finished product. Steady flow takes care of measuring the pressure at the screw tip, and on that basis constantly readjusts the screw speed. This minimizes pressure fluctuations and consequently pulsations in the melt flow, which in turn ensures significantly better semi-finished product quality and reduces the amount of scrap.

Gerold Schley is confident: “With our trade fair presentation, we will impressively demonstrate that we have understood the needs of the industry and are offering solutions. These range from optimized individual components to complete lines, including digitization tools as well to facilitate daily production and to enhance production efficiency in every aspect”. He is looking forward to many interesting and above all face-to-face conversations in Düsseldorf.

![6286x5117, 6 MB [Translate to EN:]](/fileadmin/_processed_/5/b/csm_Digitazation_5176498c8f.jpg)