Co-extrusion solutions

A variety of co-extrusion solutions for pipe and profile

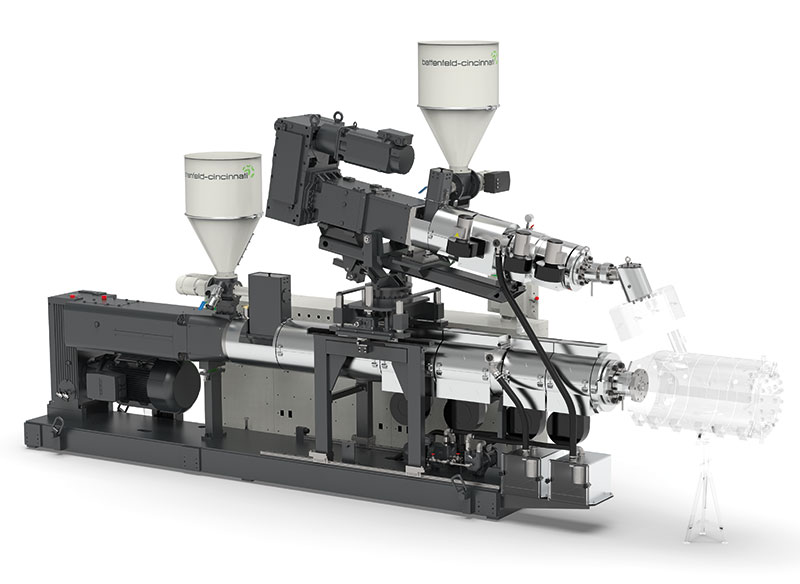

Solutions for the use of regranulate

The use of regranulate requires co-extrusion solutions. Depending on the customer's requirements, there are an almost infinite number of extruder combinations for the co-extrusion of PVC profiles or pipes. Most often, the parallel twinEX extruder is used as the main extruder in combination with a conEX NG conical extruder as the co-extruder.

Your Advantages:

- One control and control cabinet for both extruders

- One central cable solution between profile tool and extruder control cabinet

- Easy and exact extruder adjustment for different profile and 3-layer pipe tool connections

- Smallest footprint

- Various extruder combinations for high co-ex performance

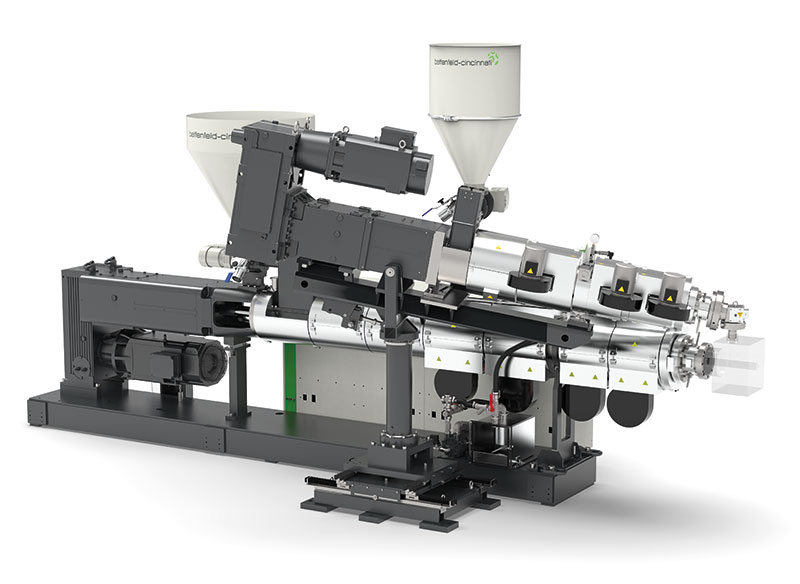

Space saver solution

The Space Saver set-up requires a smaller footprint.

The flexible frame enables easy pivoting and tilting to arrange the co-extruder to adapt to different profile tools.

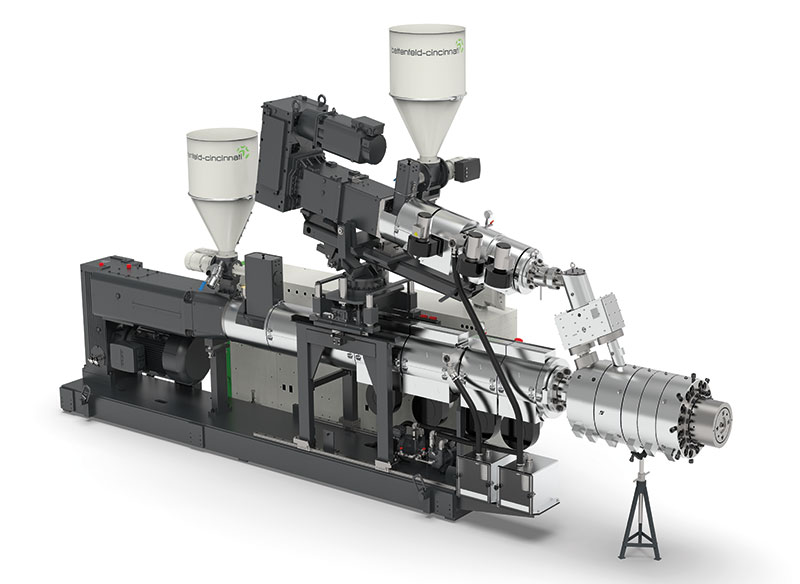

Piggyback solution

The piggyback solution saves more than space

In addition to saving space, the piggyback configuration offers a cost advantage and the additional benefits of user-friendliness and high energy efficiency.

Thanks to the coextruder’s flexible frame design, this machine combination offers maximum flexibility in die connection, so that die changes are made easy. The extruders have a common control cabinet, which saves both cost and space and makes the equipment easy to operate as well.