- battenfeld-cincinnati

- Applications

- Pipe

- District heating pipes

District heating pipes

District heating is a relatively environmentally friendly process to provide thermal energy. To transport the heat from producers to consumers, a heat-insulated pipeline system is used, which is mostly laid underground.

A reliable basis: extrusion technology from battenfeld-cincinnati provides the basic equipment for producing plastic casing pipes with a service life of more than 30 years. The pipes are resistant against chemicals and salts, physical impact and corrosion, and come with a top-class insulation effect, about 40 per cent above that of conventional pipes – for an extremely low effective heat loss rate.

On our application-optimized extrusion lines, pipes for distance heating are created to withstand operating pressures of 40 bar and water temperatures of up to 150 °C. Due to the need to withstand extreme pressures and thermal loads, the internal medium pipe inside the plastic casing pipe is made of PE-Xa, polybutylene or steel. Normal medium pipe dimensions range from DN 15 to DN 1,200. The casing pipes come in sizes of up to 2,000 millimeters.

Our products for manufacturing district heating pipes

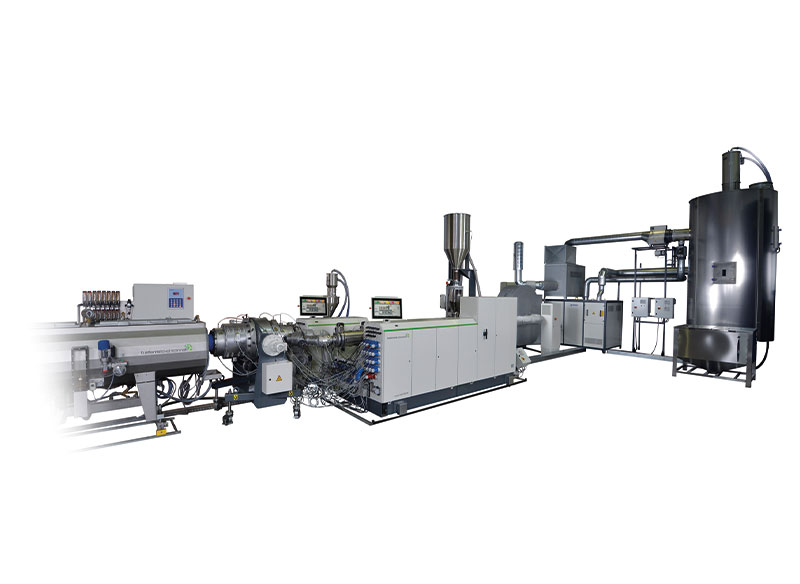

Extruder

Tools

Back to top

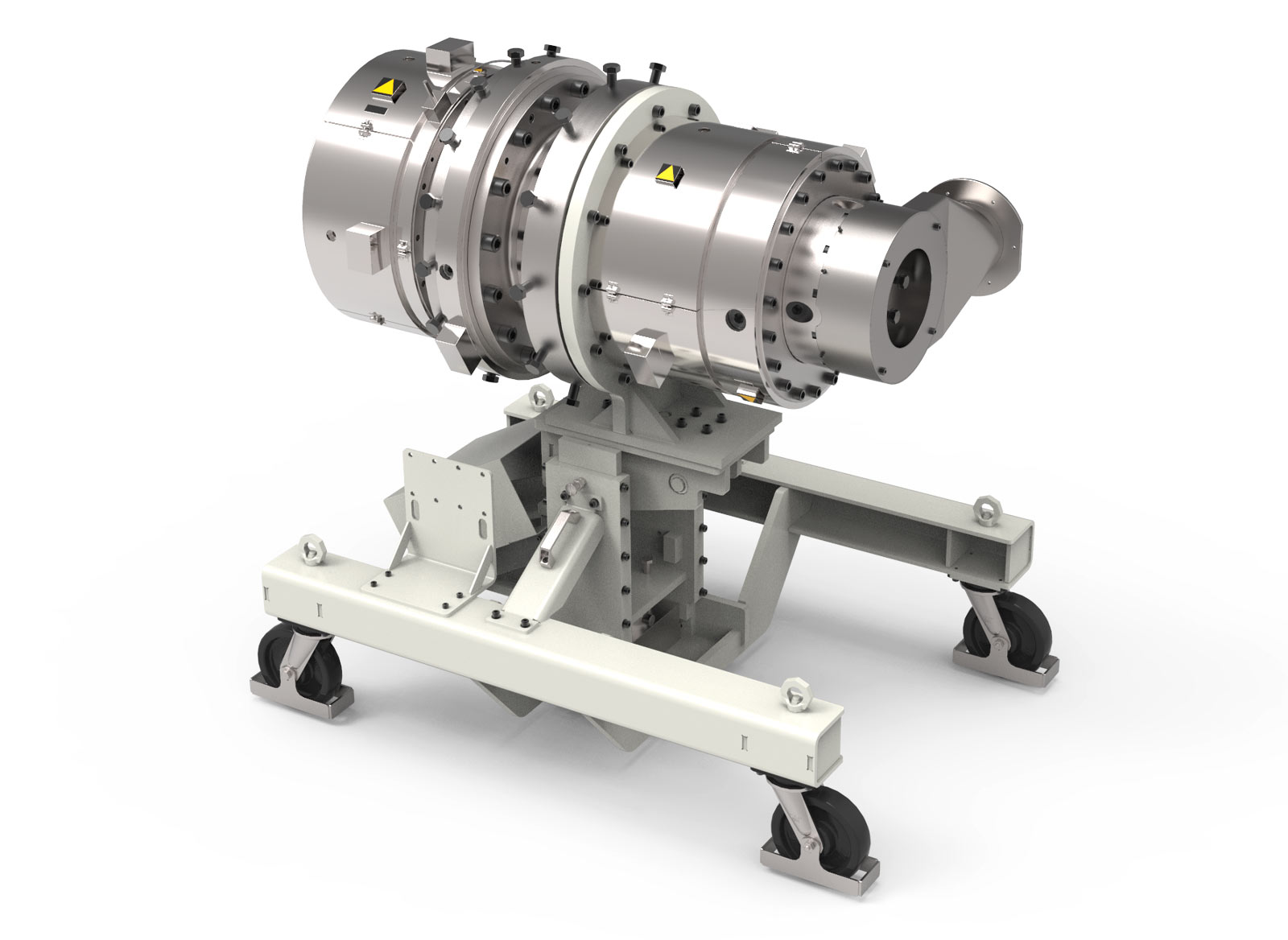

helix II PO Pipe toolings and coat coating dies

Customized mono- and multi-layer toolings for a various customer needs

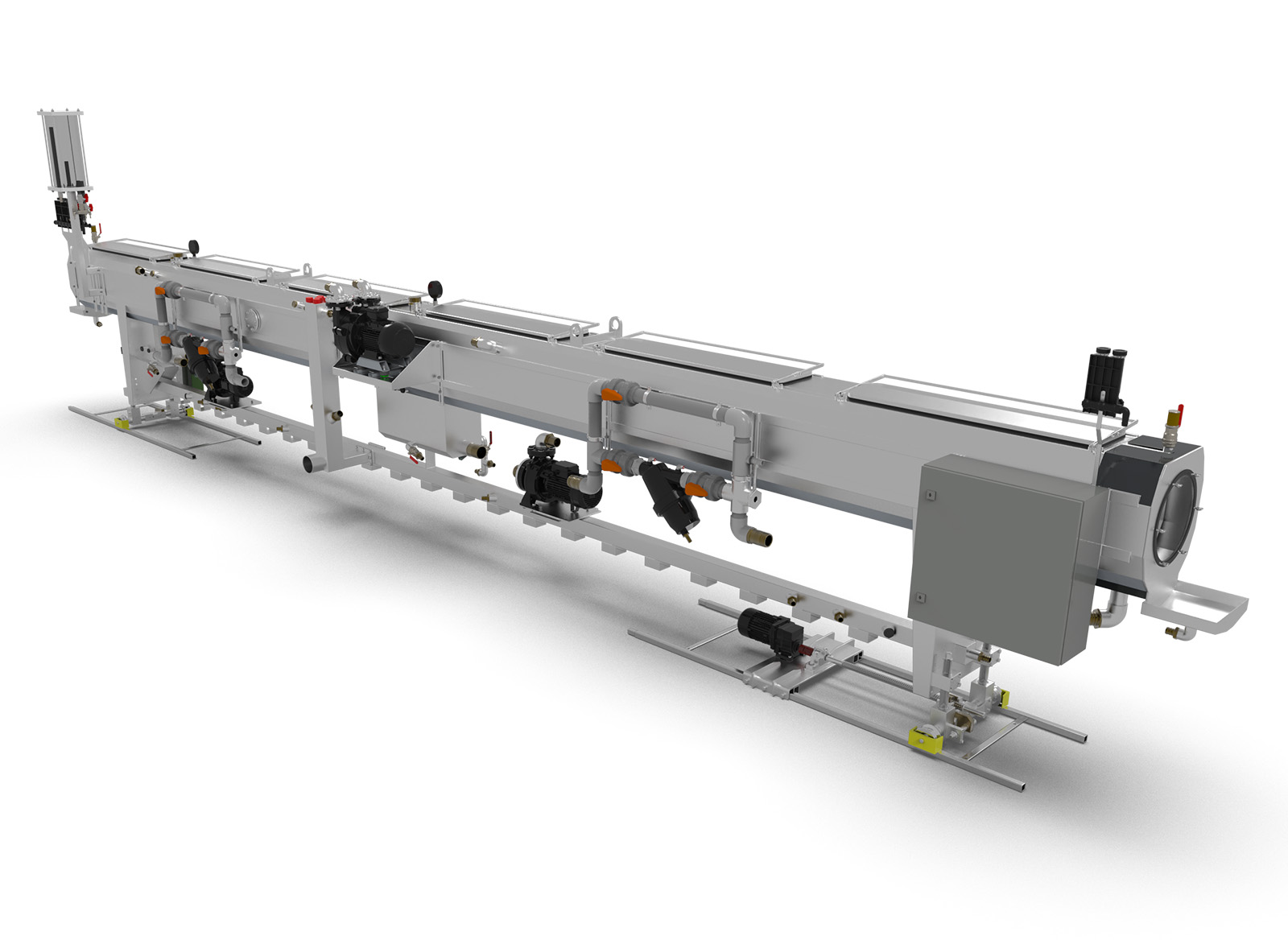

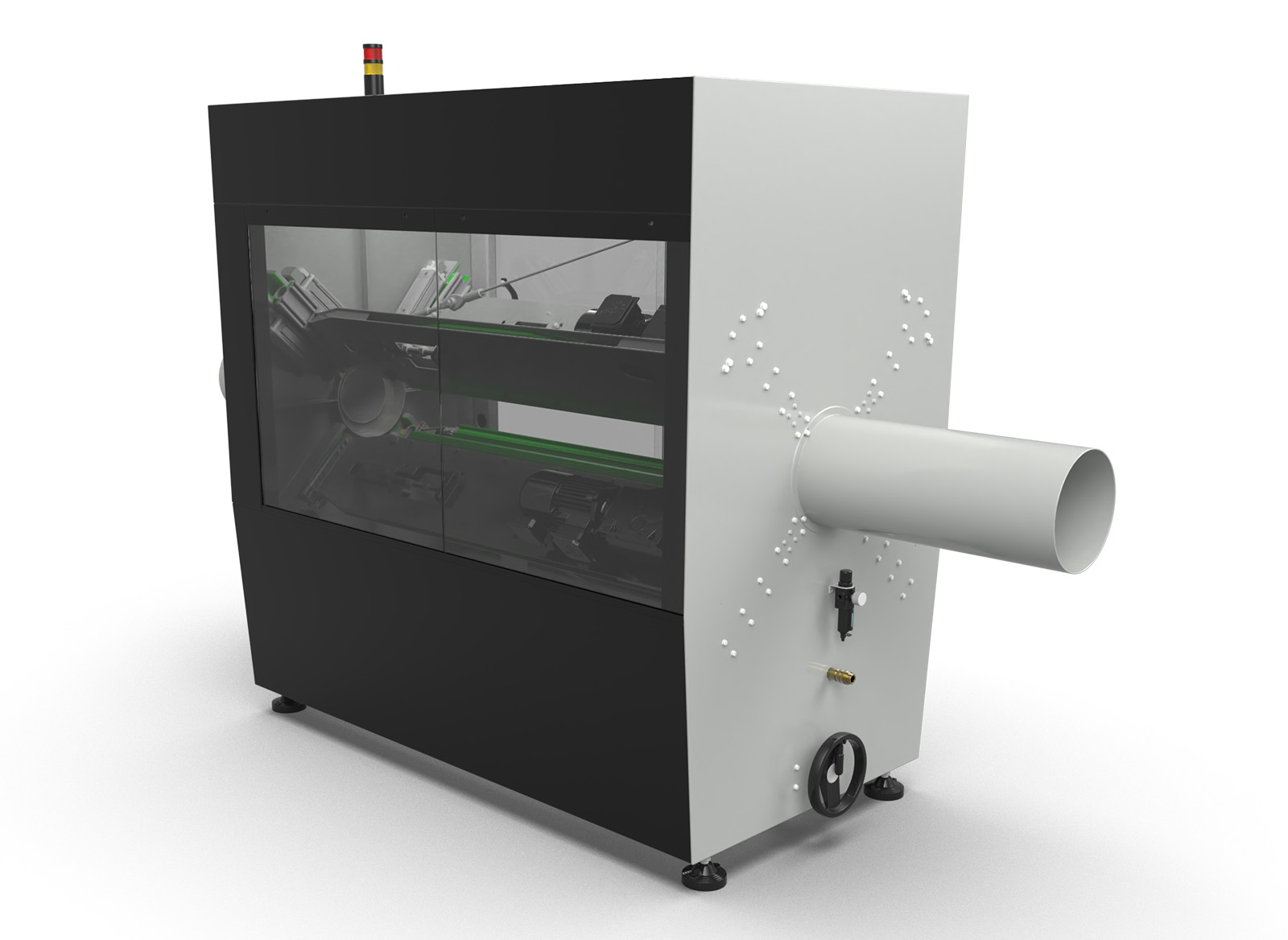

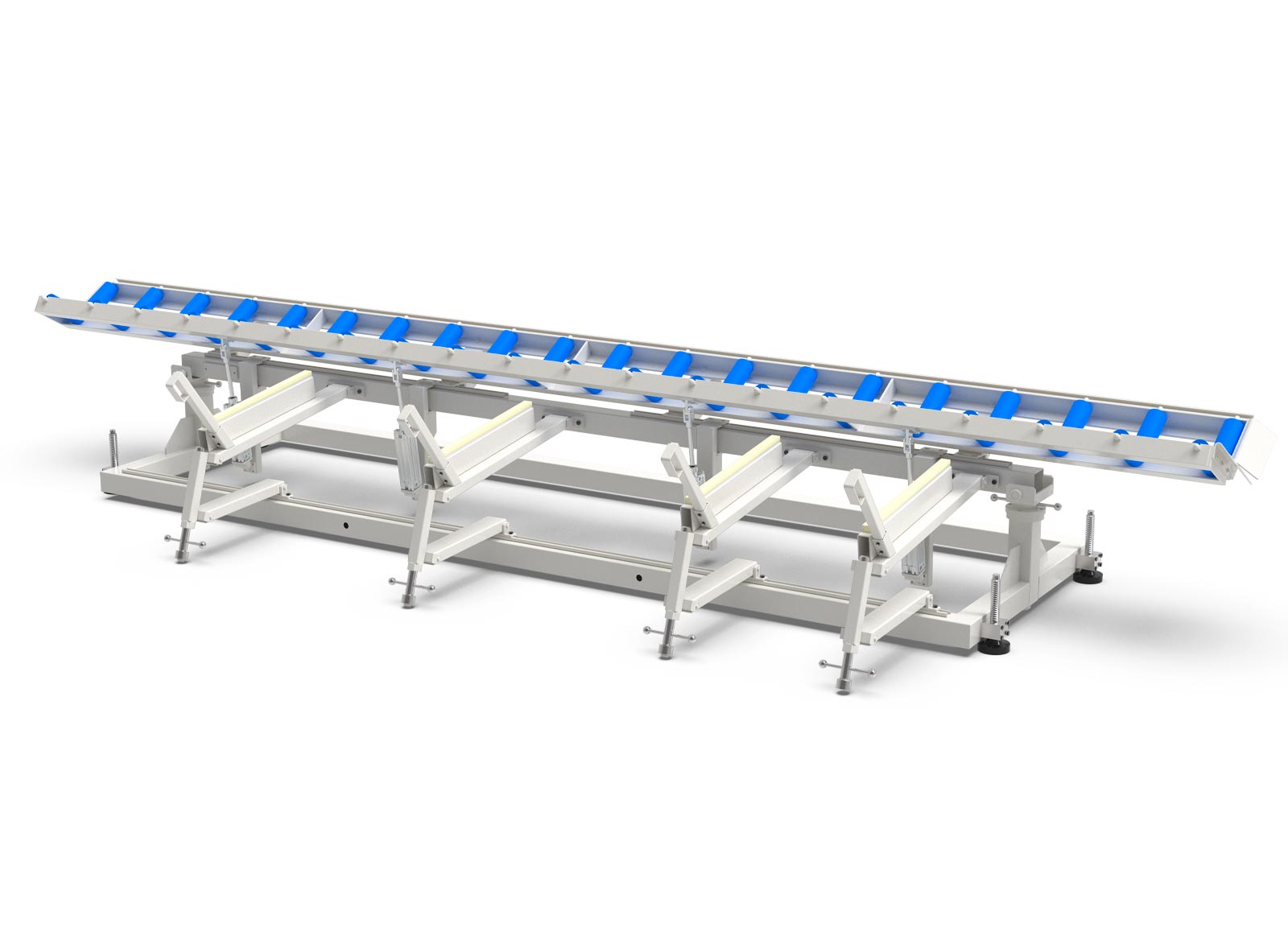

Downstream & Systems

Back to topControls & Automation

Back to top

Complete lines for pipe extrusion & special pipe applications

You will find more detailed information about the applications for our extrusion technology in our brochures.

Download now